I was using my iron to apply the heat transfer vinyl (Siser EasyWeed) and noticed that it resulted in some uneven application of the vinyl. I made an offhand remark to Greg about how I could see the benefits of having a heat press and behold! We now have a PowerPress heat press! (Thanks, Greg!)

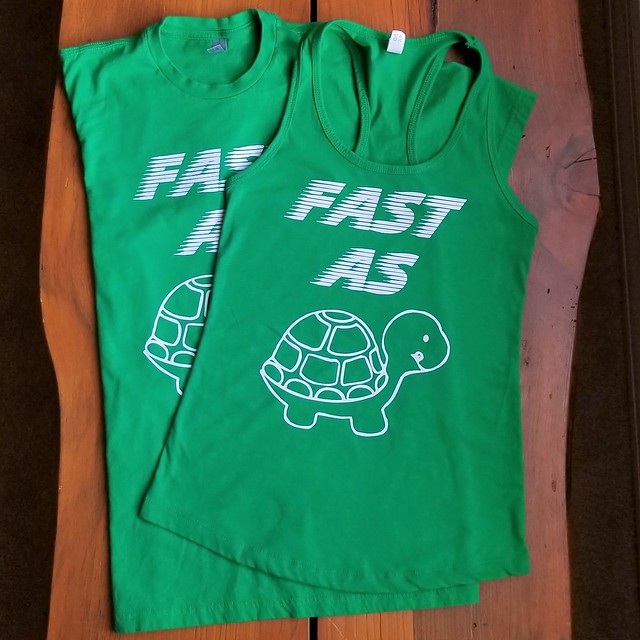

I wasn't trying to hint to Greg that I wanted a heat press - that's not how I roll. But at the same time, I'm not complaining that we have one, especially since I was able to make these team shirts for Greg's coworkers for the local Rugged Maniac race.

The heat pressing part was very straight forward. What took the longest was the cutting and weeding of the vinyl. I also had to re-cut a few pieces of vinyl since some of the cut lines were missed in the cutting (so then I couldn't weed completely) or when I was weeding, some small pieces came off that weren't supposed to.

The design came from one of Greg's coworkers, and I was pleased with how well the Silhouette software handled converting the picture file to a cut file. (See: How to cut a JPEG with Silhouette Studio - the functionality is still there in the Silhouette software, though the exact path to get there may have changed)

Before I embarked on making the shirts, I also did some research on Pinterest and the Silhouette School blog. Based on this Cheaper Alternative to Pressing Pillows: Pressing Pads! post from the Silhouette School blog, I got these Tee Pad It pressing pads from Heat Press Nation. These worked well to prevent seams from getting in the way of evenly applying the heat transfer vinyl, which I had happen on one of my first heat transfer vinyl shirts that I did with my iron.

I have a couple of other projects I'd like to do with heat transfer vinyl, the Silhouette, and the heat press, I just need to find the time to do them along with all the other craft projects!